Time for the World to Stop the Export of Used Cooking Oil

At the BioCube Corporation, we firmly believe that the recycling and processing of used cooking oils (UCO) into biodiesel represents a key pillar in the

Protecting Australia’s Limited Fuel Reserve by Processing Waste

Our Fuel Supply is Scarce It is a well-known fact that Australia’s reserve of diesel fuel is limited. Indeed it is estimated by the Australian

There is no ‘Planet B’, so how do we look after ‘Planet A’?

Greta Thunberg is driving a global climate movement. The question is how, do we carry this momentum, and what role can the BioCube™ play?

The BioCube Corporation and Penta Gas Sistems sign distributorship agreement for BioCube™ in Indonesia

It gives us great pleasure to announce the appointment of PT Penta Gas Sistems as distributors for the BioCube Corporation in Indonesia.

Waste Cooking Oil – an Asset or a Liability?

Waste cooking oil (‘WCO’ – also commonly referred to as ‘used cooking oil’ or ‘UCO’) refers to edible oil that has been used for cooking

The BioCube™ Corporation Website Launch Press Release

2020 has been a difficult year for the entire world. Lives and livelihoods have been lost, communities have been devastated and economies have crumbled. All

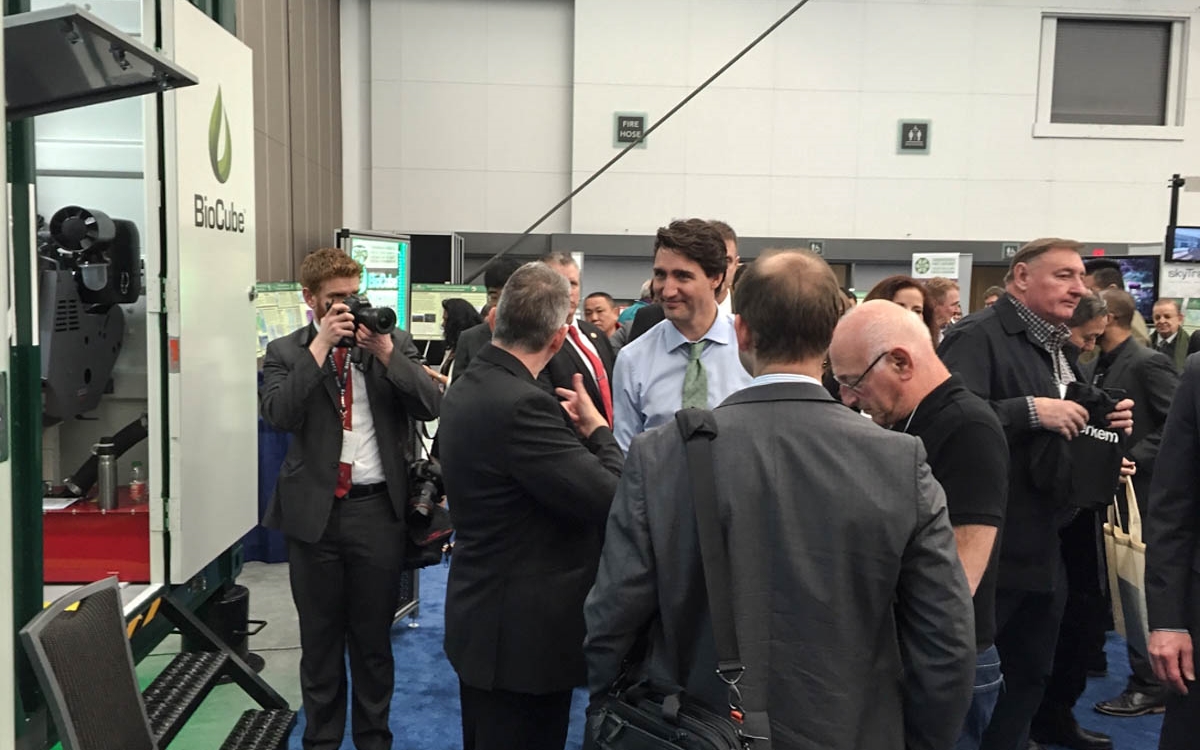

Justin Trudeau, Prime Minister of Canada, Visits The BioCube™

The BioCube Corporation was delighted to have The Right Honourable Justin Trudeau, Prime Minister of Canada visit the BioCube™ at the GLOBE Conference in Vancouver.

BioCube Co. Formalises Partnership with CBVL Robotics Inc., Canada

The BioCube Corporation took another significant step forward with the signing of a contract to manufacture the BioCube with CBVL Robotics Inc, of Coquitlam, BC,

BioCube™ Wins Innovative Green Technology Award

The BioCube Corporation is pleased to announce that it has won the prestigious Global Innovative and Friendly Energy Solution Award at the Biofuels Conference held